DESIGN OF EXPERIMENTS

"Those who ignore statistics are condemned to reinvent

it. Statistics is the science of learning from experience" - Bradley

Efron

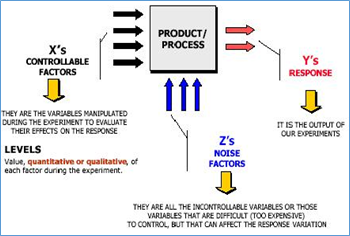

In the

Manufacturing Industry, some processes are so complex that even a very

experienced and competent engineer would not necessarily know how to identify

the best settings for your manufacturing equipment. In addition, most processes

are defined by multiple factors or inputs, each of which will change the

process output. How do we analyse the right setting for each factor? You obviously

cannot adjust one factor at a time and experiment in a disorganized way.

Design of

Experiments (DoE) provides an organization with a powerful tool that can help

them develop a model in a very practical, cost-effective, and flexible way,

allowing them to quickly identify the correct process settings.

It’s a

systematic, rigorous approach to engineering problem-solving that applies

principles and techniques at the data collection stage so as to ensure the

generation of valid, defensible, and supportable engineering conclusions.

It has

proved to be very effective in providing a greater understanding of any

process, leading to improvements in process yield, process performance, and

process variability. It also highlights opportunities for quality improvement.

It is therefore a powerful tool for process validation,

which is a requirement in heavily regulated industries such as the Automotive,

Aerospace, Pharmaceutical, and Medical Devices industries among others. For

example, the International Organization for Standardization (ISO) requires

process validation as a regulatory requirement. Design of experiment (DOE)

statistical methods will allow these requirements to be met with an efficient

use of resources (personnel time, machine time, materials, etc.) and at the

same time provides detailed analysis, gives information on reproducibility and

errors, and provides a predictive capability. Applying DOE reduces the size and

hence the cost of process validation trials.

This one

day course will provide you with a comprehensive overview of the Design of

Experiments Process and how you can apply it to your organization.

This

workshop can also be delivered in-house as a stand-alone training workshop or

integrated into wider improvement activities.

We will be happy to discuss our Design of Experiments course in the context of your own business needs, so please contact us via email at compete@cforc.org or phone +44 (0)28 9073 7950 or our Dublin office +353 8 7224 2575 for more information.