SINGLE MINUTE EXCHANGE OF DIE

REDUCTION OF “SET-UP” OR “CHANGEOVER” TIME

SMED or Quick Changeover is

one of the key Lean tools developed to reduce setup times by implementing a

quick changeover of the activities that create and support your product or

service. While it was developed by the Automotive Industry, its application

goes beyond the Manufacturing sector to also cover the Service and Customer

Support sectors.

It is

a system that reduces dramatically the time it takes to complete equipment or

process changeovers by reducing waste. It provides a rapid and efficient way of

converting a manufacturing process from running the current product to running

the next product. This rapid changeover is key to reducing production lot sizes

and thereby improving flow.

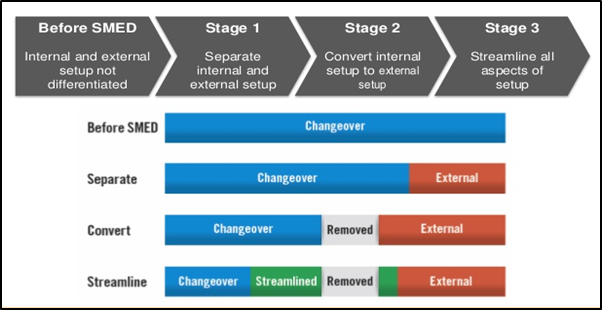

The essence

of the SMED or Quick Changeover system is to convert as many changeover steps

as possible to “external” steps (performed while the equipment or process is

running), and to simplify and streamline the remaining steps.

A successful SMED program will have the following benefits:

· Lower manufacturing cost

(faster changeovers mean less equipment down time)

· Smaller lot sizes

(faster changeovers enable more frequent product changes)

· Lower inventory levels

(smaller lot sizes result in lower inventory levels)

· Smoother start-ups

(standardized changeover processes improve consistency and quality)

· Improved responsiveness

to customer demand (smaller lot sizes enable more flexible scheduling)

This

practical and highly interactive course builds on these principles and will

provide participants with a structured methodology to identify potential opportunities

and how you can implement it to your organization.

WORKSHOP CONTENT

Introduction

·

Background

and History

·

Waste

Management Concepts

·

Traditional/Strategic

Setup Approach

·

Maintenance,

Organization and Housekeeping – Basic building blocks for SMED

SMED Quick Changeover Basics

·

Definition

·

Benefits

·

How

to Identify Opportunities

·

Types

SMED Implementation Process

·

Identify

the pilot area

·

Documentation

of the Present State

·

Identification

and separation of Internal and External Elements

·

Convert

Internal Elements to External Elements

·

Streamline

the Remaining Elements

·

Evaluation

of Change

Verification and Standardization

We will be happy to discuss our Single Minute Exchange of Die course in the context of your own business needs, so please contact us via email at compete@cforc.org or phone +44 (0)28 9073 7950 or our Dublin office +353 8 7224 2575 for more information.